Introduction

Flow monitoring is essential in many industrial and commercial systems, but transient fluctuations in flow can cause unnecessary alarms, leading to downtime and inefficiencies. This blog explores how Proteus Industries utilizes hysteresis—a built-in delay in alarm triggering and transitions—to prevent false alarms in paddlewheel flow switches and meters, such as our 8000 Series, that rely on magnetic sensing.

The Challenge: False Alarms in Flow Monitoring

Flow rates naturally fluctuate due to a variety of factors such as pump cycles, pressure changes, or turbulence in the system. In flow switches with magnetic sensing, these brief fluctuations can potentially trigger an alarm or notification even if the flow hasn’t actually dropped or increased beyond a critical threshold. In the extreme, false alarms disrupt operations, cause unnecessary maintenance checks, and reduce overall system efficiency.

The Solution: Flow Switch Hysteresis

Hysteresis adds intelligence to the alarm system by requiring a sustained change in flow before triggering an alert. Instead of reacting immediately to every fluctuation, hysteresis introduces a short delay, ensuring that alarms are only triggered when there is a sustained deviation from the set flow threshold, rather than a brief or transient fluctuation.

How Hysteresis Works in Proteus’ Paddlewheel Flow Meters

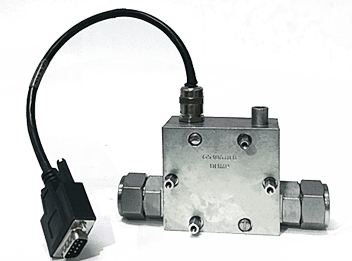

In Proteus Industries’ paddlewheel flow meters, magnets are embedded in the spinning rotor to generate pulses that correspond to the volumetric flow rate. A sensor—typically a Hall-Effect sensor—detects these pulses. The time between pulses is inversely proportional to the flow rate: shorter intervals indicate higher flow and longer intervals indicate lower flow. Proteus flow meters, such as the 8000 Series feature both low-flow Warning and Alarm statuses that are indicated by a tricolor LED on the device and communicated to the user’s PLC. The Warning status alerts the user/system to a potential low flow condition, while the Alarm trip point will signal the user/system to shut down the process.

For rising flow rates, a hysteresis value equal to 5% of the upper flow limit of the device will apply to flow status transitions from Alarm to Warning and from Warning to Flow OK. If the liquid flow rate falls below the warning limit value or alarm trip point value and thereafter begins to increase, a hysteresis band will begin at the lowest flow rate at which flow was measured immediately prior to the increase. The flow status of the device and the corresponding LED color will not change until the flow rate has increased beyond the hysteresis band, even if the actual liquid flow rate increases above the warning limit value or alarm trip point value prior to doing so.

Without hysteresis, a temporary change in flow could trigger an alarm. Hysteresis prevents this by requiring the condition to persist for a predefined period before signaling an issue.

Key Benefits of Hysteresis in Proteus 8000 Series Flow Meters

By integrating hysteresis into flow monitoring systems, Proteus’ paddlewheel flow meters offer several advantages:

- Fewer False Alarms: Eliminates unnecessary alerts caused by brief flow fluctuations.

- More Reliable Monitoring: Ensures alarms indicate actual, sustained issues rather than short-lived variations.

- Reduced Downtime: Prevents system shutdowns or manual interventions due to false alarms and allows operators to focus on genuine flow issues rather than investigating false alerts.

Conclusion

Hysteresis is a simple yet powerful feature that enhances the reliability of Proteus Industries’ paddlewheel flow meters and switches that use magnetic sensing. By introducing a short delay before triggering a change in flow status, hysteresis effectively prevents unnecessary disruptions caused by transient flow fluctuations. This results in more stable operations, reduced downtime, and improved overall efficiency and reliability.